Our own jigs and fixtures designs, programs and builds individual automation solutions for injection molding productiong according to your product-specific requirements. Qur core competencies are fully automatic assembly systems as well as complex production cells with insert, provision und various quality inquiries.

Product specific gripper systems

Product-specific assembly, testing and feeding systems

Mounting island consisting of three assembly workstations for the assembly of guide sleeves

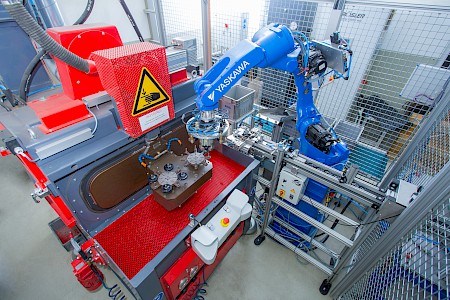

Equipping of fully automatic blast machine using 6-axis robot

Fully automated assembly system for head restraint guide sleeves