Quality knows no competition. The measuring technology at Ros carries out all the steps in the dimensional component analysis. It acts as an interface in the entire process between project management, tool shop, production as well as the customer and is integrated from the feasibility analysis through initial samples to the final sampling in the entire process.

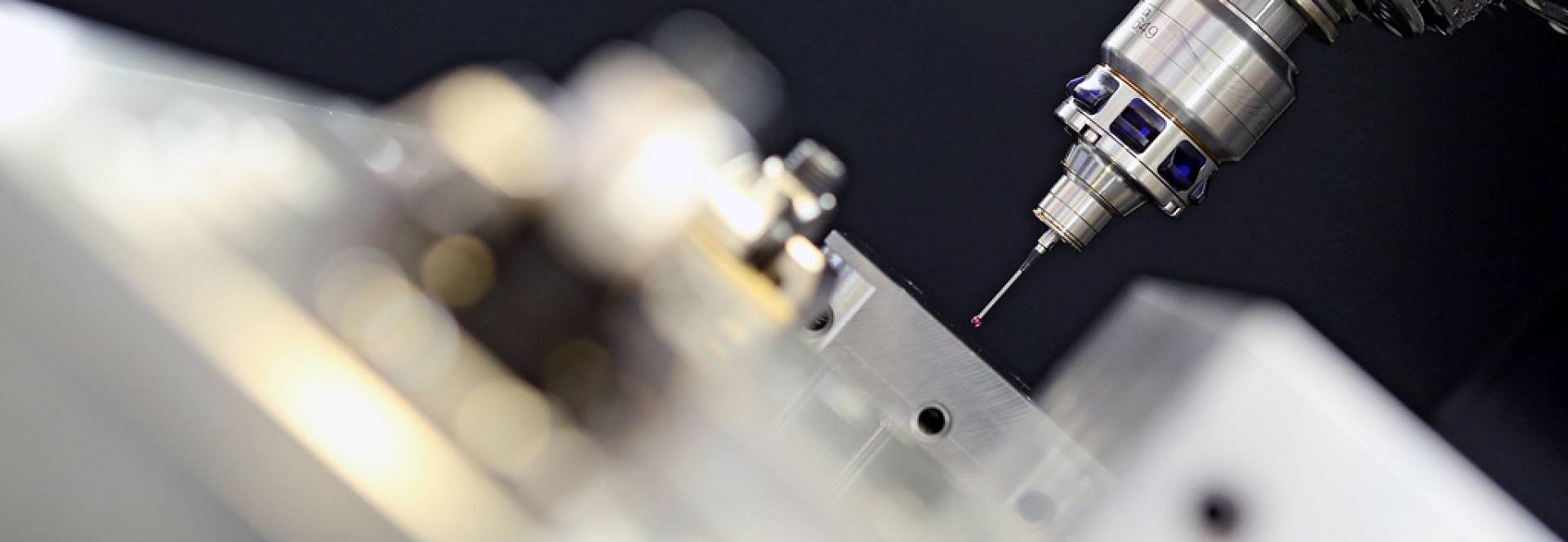

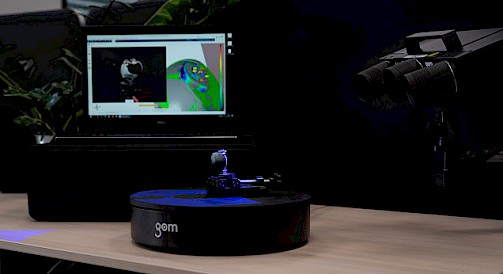

In metrology, only highly modern measuring methods are used. In this way, components can be measured tactilely, optically and non-contact. Surface and contour measurements are also carried out by our experienced measurement technicians on your components.

Furthermore, all production-relevant additional information about the components are passed to our own tool shop to ensure the most efficient tool optimization.

By means of highly accurate scanning technology, functional areas can be recorded and processed using special software. This allows us to achieve tight shape and position tolerances.